Types of Gutters

Iron castings

Gutter systems made of cast iron, an alternative to lead gutters, were first used in the late 18th century. Eaves gutters could be mass-produced out of cast iron because of the material’s rigidity and impermeability, in contrast to lead, which could only be used as a liner within wooden gutters.

The installation was only one step and did not involve the use of heat. They could be fastened in place by affixing themselves straight to the fascia board. Cast iron gutters are still specified for restoration work in conservation areas, however, cast aluminum gutters produced to the same profile as the cast iron gutters are typically used in their place.

Gutter systems constructed of extruded aluminum can be cut on-site to lengths of up to 30 meters in a variety of profiles by beginning with a roll of aluminum sheet. They come with internal brackets that are spaced 400 mm apart.

UPVC

UPVC guttering is a common material used in the construction of residential buildings in the UK. In the 1930s, pipes made of polyvinyl chloride (PVC) were initially manufactured for use in sanitary drainage systems.

In 1933, polyethylene was discovered and developed. In the 1950s, the Netherlands was the first country in the world to install pressurized plastic water pipes for drinking water. The use of plastic for rainwater pipes, guttering, and downpipes was pioneered in the 1960s, and this was followed by the development of PVC soil systems, which were made commercially viable by the advent of ring seals.

Following the publication of a British Standard for soil systems, local authorities began to require the use of PVC systems. By 1970, more than sixty percent of newly installed rainwater collection systems were made of plastic. Since 2004, there has been a European Standard known as EN607.

It has a life expectancy of fifty years, is simple and inexpensive to install, is lightweight, requires very little care, and has a long installation time. Because the material has an unfavorable coefficient of thermal expansion of 0.06 mm/m°C, certain allowances need to be made for it throughout the design process.

A 4-meter gutter that is exposed to temperatures ranging from 5 degrees Celsius to 25 degrees Celsius will require space to expand equally to 30 times 4 times 0.6 millimeters (mm) between its end stops. A roof that is 600 square feet (56 square meters) area can be drained with a gutter that is 4 inches (100 millimeters) wide and has a single downpipe that is 68 millimeters (2.7 inches) in diameter.

Stainless steel

Guttering systems made of high-quality stainless steel are available for residential and commercial construction projects. Stainless steel has a number of benefits, including its resistance to corrosion, its ease of cleaning, its superior looks, and its longevity.

When compared to concrete or wood, a gutter made of stainless steel will go through significant cycles of thermal expansion and contraction as the temperature changes. If adequate allowance for this movement is not made during the installation process, there is a possibility that the gutter will become misshapen, which could result in improper drainage from the gutter system.

Seamless gutters

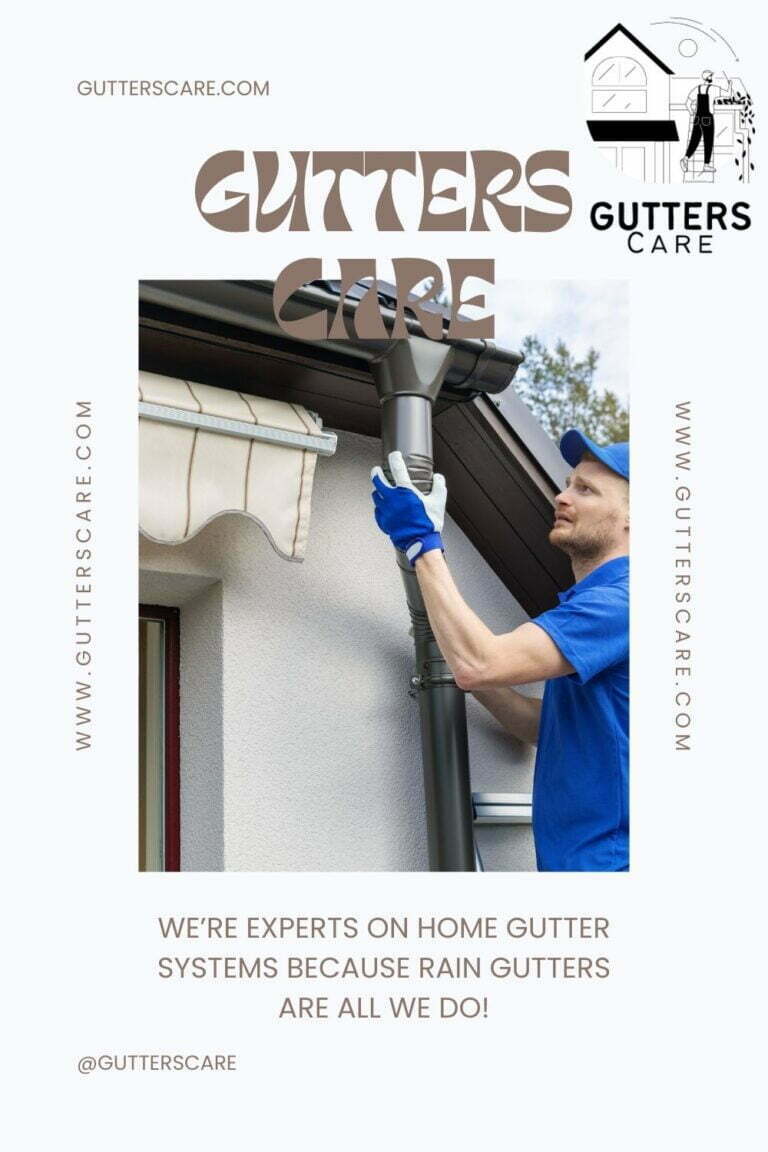

Seamless gutters have the advantage of being able to be made on-site with a portable roll-forming machine to match the dimensions of the structure.

Additionally, seamless gutters are typically installed by skilled tradesmen. If it is placed correctly, a seamless gutter can survive for more than 30 years. It has a thickness of.027 inches.

Zinc

Because of its resistance to corrosion, guttering is frequently fabricated from zinc-coated mild steel in both commercial and residential designs. BS EN612:2005 is the standard that governs metal gutters with bead-reinforced fronts in the United Kingdom.

Finlock gutters

Finlock gutters, which are just concrete gutters marketed under a brand name, are adaptable enough to be used on a wide variety of structures. When there was a shortage of steel and a surplus of concrete in the 1950s and 1960s, these were utilized as a replacement for cast iron gutters on residential houses.

This was done since there was a surplus of concrete. They were rejected once it was discovered that differential movement might open joints and enable dampness to infiltrate, although an aluminum and bitumastic liner could be installed in them instead.

The visible gutter on a Finlock concrete gutter unit is one of two troughs that make up the unit. The other trough rests across the cavity wall of the building. To create lintels for doors and windows, the blocks, which can have a thickness ranging from 8 to 12 inches (200 to 300 millimeters), can be linked together with reinforcing rods and concrete.

Vernacular buildings

Any material that is readily available in the area, such as stone or wood, can be used to make guttering. Pitch or bitumen can be used to fill the pores of porous materials.

Shapes of Gutters

The K-Style gutter, the round gutter, and the square gutter are the three most common forms of gutters used in Western buildings today. In days gone by, there were 12 different shapes and styles of gutters.

The letter designation “K” is tenth out of a total of twelve, which is where the name “K-Style” originates from.

Recent Articles and Content about Gutters:

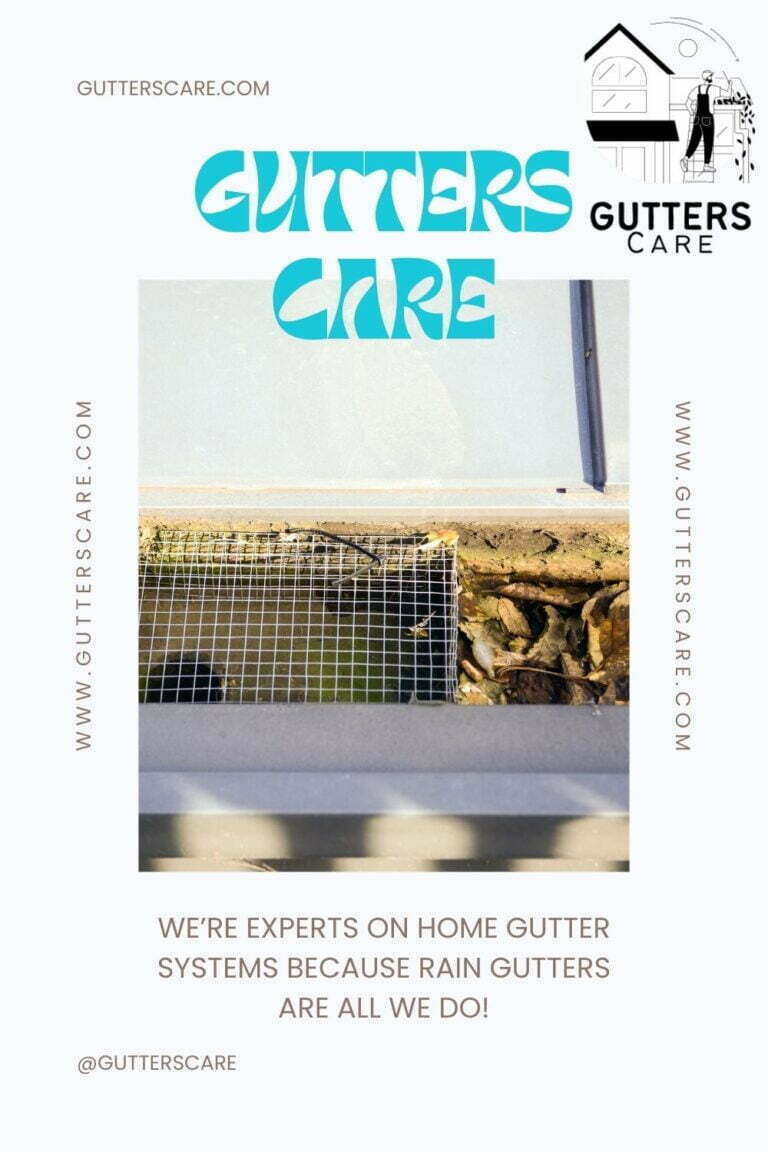

- Ultimate Guide to the Best Rated Leaf Guards for Gutters

- Ultimate Guide to Installing Leaf Gutter Guards: Say Goodbye to Clogged Gutters!

- Safe Haven Gutters vs. DIY: Which Is the Best Shield for Your Home?

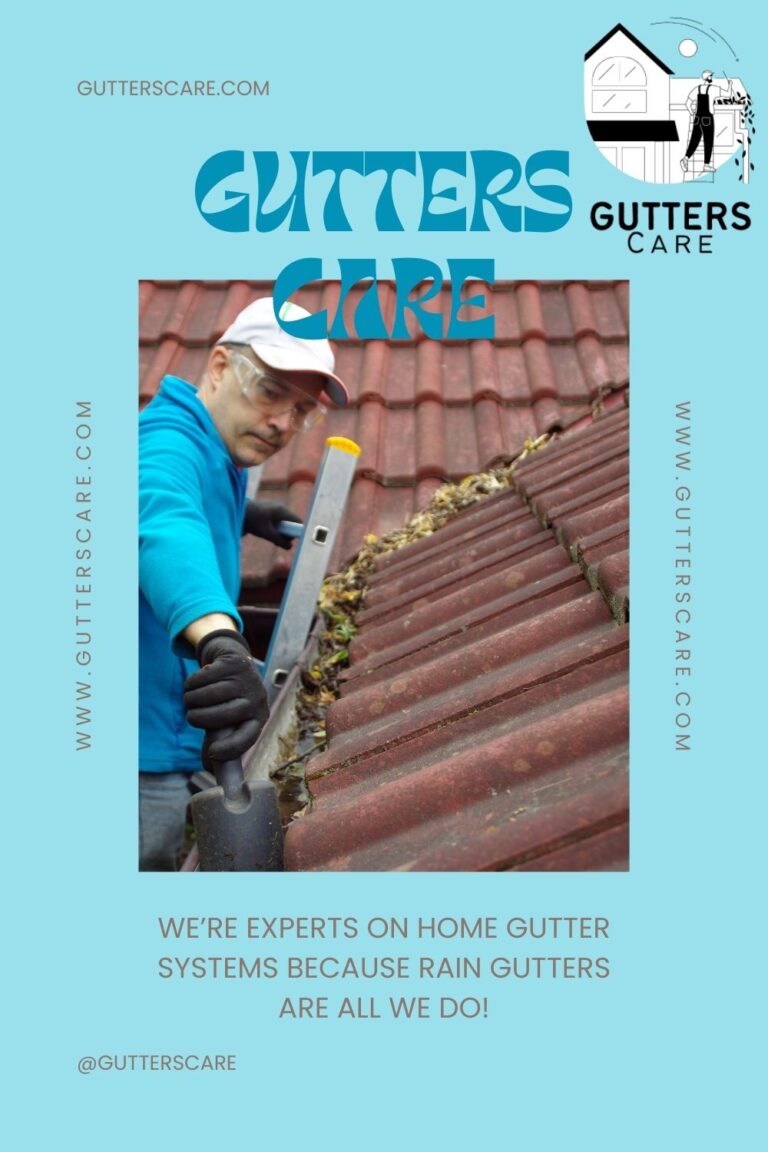

- Ultimate Guide to Essential Gutter Cleaning: Tips, Tools, and Techniques

- Dangers of Stagnant Water in Gutters: Causes, Effects, and Solutions